Issue Management

- Issue capturing

- Issue monitoring

- Issue analysis 8D

- Objective data collation

- Report Generation

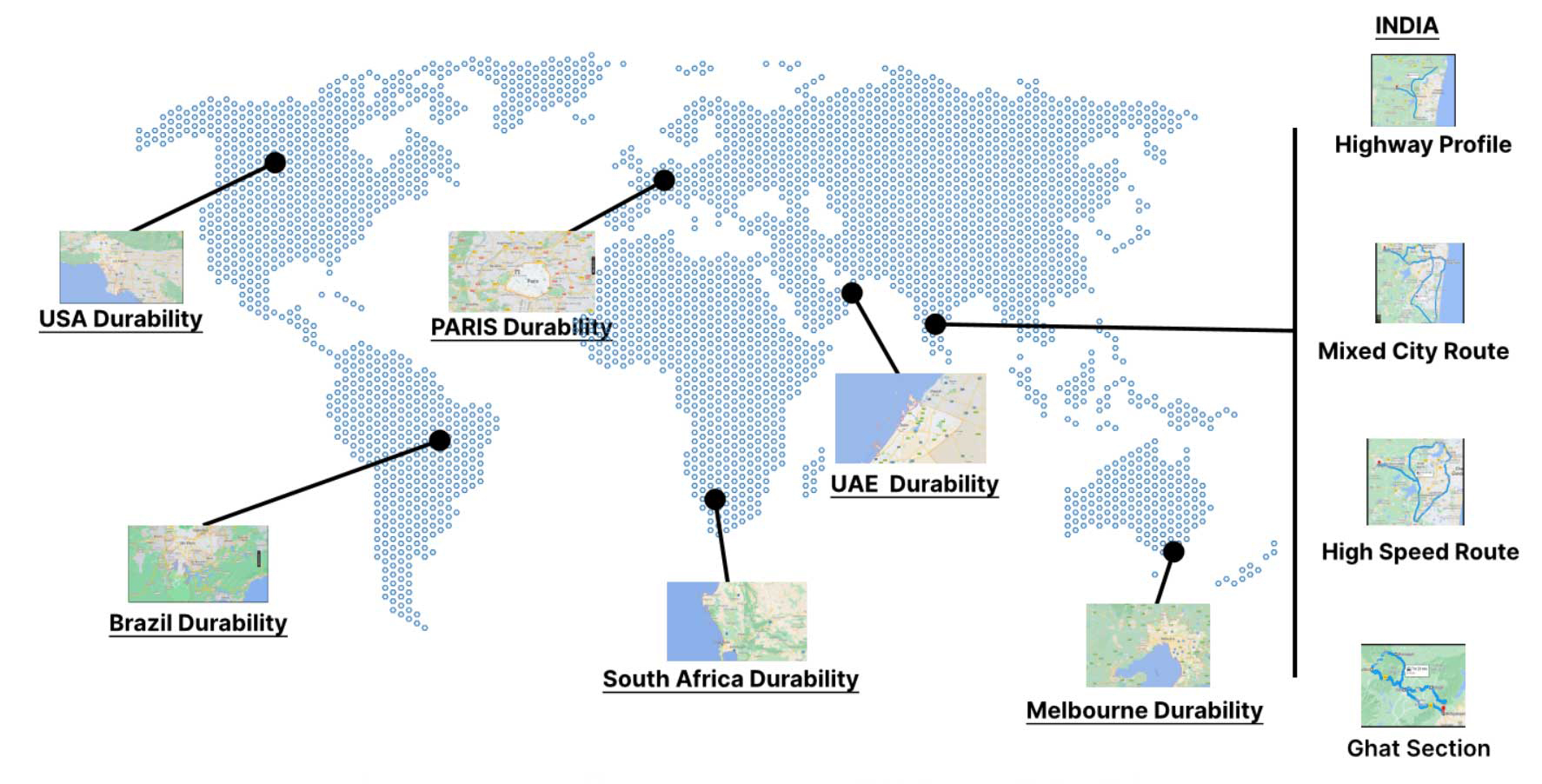

On road Fleet and Durability Testing in PAN India and Global Locations.

24x7 Operations for Fleet Management

Robust Drive Training, Drive Evaluation and Selection Process.

Performance Testing on Test Track, Specific Road Profiles and Terrains

We are committed to ensuring the highest standards of quality and reliability in components' testing. To achieve this, we conduct a comprehensive range of durability and performance tests, including Vehicle Simulation Setup for E&E Components, Bench Testing for Switches, and Sun visor Durability Testing.

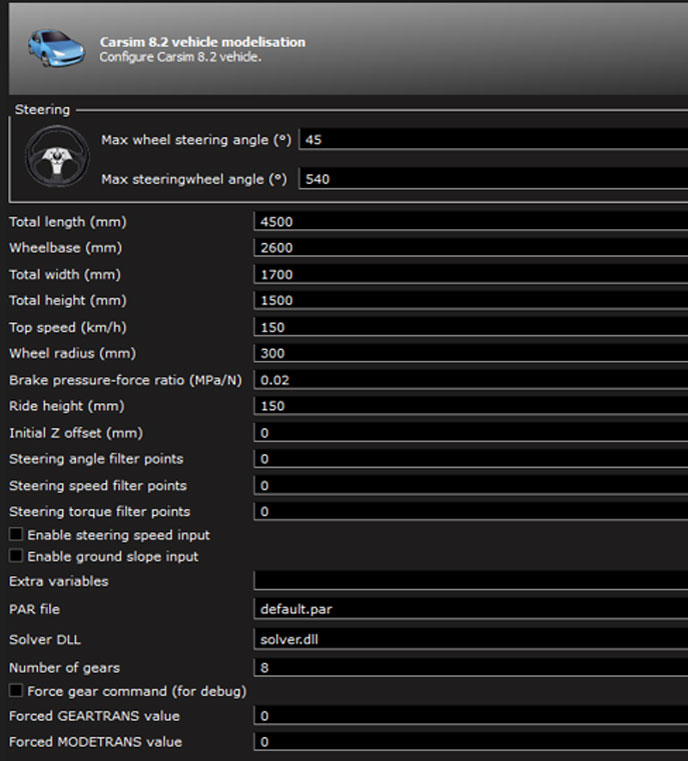

A Versatile Tool that enables users to configure, develop, run simulations, and analyze results for vehicle models and driver behavior, allowing testing and validation across various application cases.

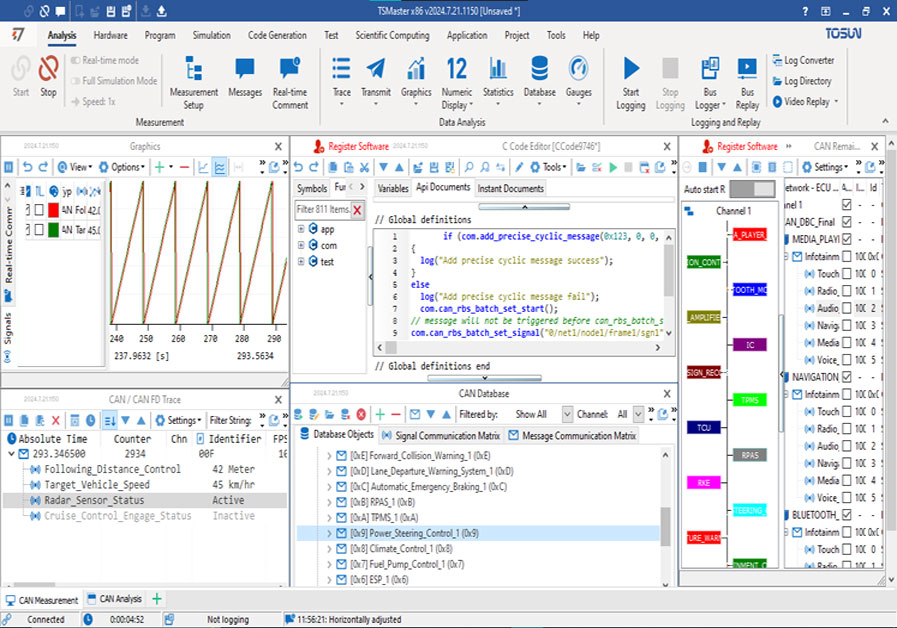

CAN (Controller Area Network) network validation. It highlights the essential role of validating communication protocols within a CAN network, emphasizing the accurate transmission and reception of messages among electronic control units (ECUs). The importance of this validation is underscored in its contribution to ensuring the optimal performance and functionality of systems utilizing CAN communication, particularly in diverse applications such as automotive and industrial systems.

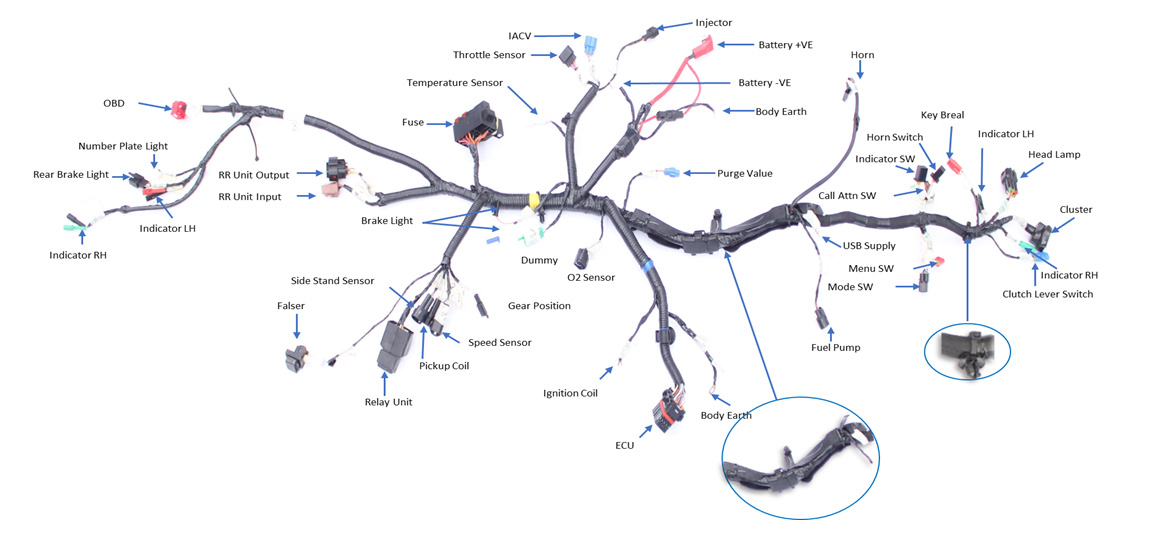

HARNESS LAYOUTS & TESTING ANALYSIS

Rapid and Reliable Inspection of PCBs with Digital Microscopy

3D image is important for inspecting PCBs, then a microscope image is required.

Efficient screening and document more results in less time using a digital microscope with camera.

Error Mode Verification

Error Strategy & DTC verification

Diagnostic verification & validation

Corrosion evaluation procedure used by CAPCP Engineering services will evaluate the vehicles with 4 steps evaluation procedure with the appropriate rating scale, Corrosion action priority score will be arrived based on resultant rating proportionate to service life of vehicle

| Corrosion Rating scale (1) | ||||||

|---|---|---|---|---|---|---|

| Photo | No corrosion |  |  |  |  |  |

| Stage of corrosion | No corrosion | Light rust, Blushing or discoloration of surface | Little blistering and rust, No scaling, paint peeling or metal loss | Blistering, heavy rust, scabbing and rust bleed, Small amounts of metal and paint peeling | Severe rusting and Scabbing, Heavy flakes and layers removed | Large chunks falling off, perforations, Non functional or non serviceable |

| Rating | Level 0 | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 |

| How customers will perceive? | No Problem | Not acceptable | Not acceptable | Not acceptable | Not acceptable | Not acceptable |